Haulage scraper conveyor

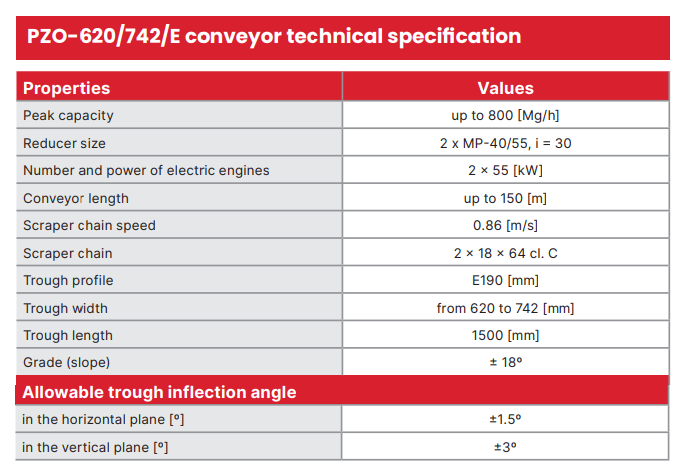

Haulage scraper conveyor PZO-620/742/E is designed for run-of-mine haulage from stone and coal workings – horizontal or sloped longitudinally, up to ±18º, or transversely, at least ±8º. They can be operated in underground workings of mining factories in rooms with methane explosion hazard grade ”a”, “b”, “c”, and coal dust explosion hazard class A and B.

Haulage scraper conveyor PZO-620/742/E is designed for run-of-mine haulage from stone and coal workings – horizontal or sloped longitudinally, up to ±18º, or transversely, at least ±8º. They can be operated in underground workings of mining factories in rooms with methane explosion hazard grade ”a”, “b”, “c”, and coal dust explosion hazard class A and B.

Depending on the needs, the PZO-620/742/E conveyor can be positioned directly on footwall,

with drive seated on a sub-base, or partially suspended, with drive suspended above the receiving conveyor or carts. Conveyor set-up with the drive on a sub-base or suspended is as follows: return station and a couple of troughs are placed on a footwall, and the remaining part of the trough line with drive is suspended or placed on a sub-base above the run-of-mine receiving machine.

The method of conveyor advancing over the footwall is up to the user. PZO-620/742/E conveyor consists of the following elements:

- drive assembly, equipped with two engines with the power of 55 kW or 30 kW, two angular type MP-40/55 gears, and two flexible couplings,

- reversing station with integral chute or a separate charging hopper,

- drive sub-base or suspension,

- conveyor trough line made of troughs with E190 profile, 620 in width, up to 742 mm and 1500 mm in length, with up to 20-mm thick wear-resistant side sheet metal,

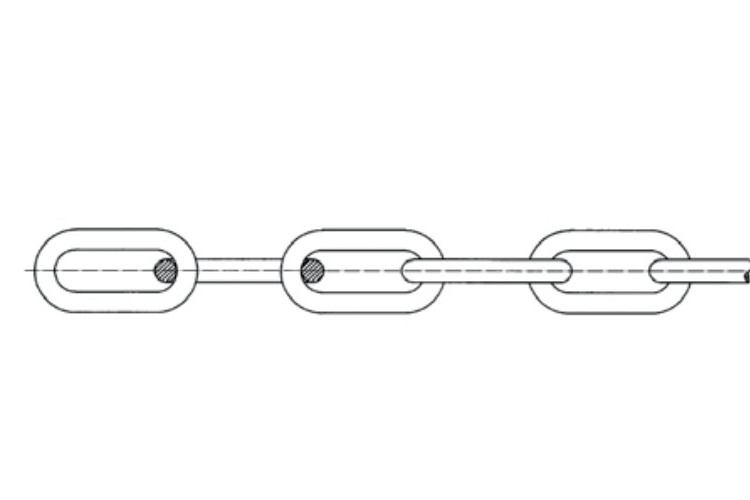

- conveyor route made of two or three scraper chain strands 18 x 64 connected by means of clamping rings, screws and nuts,

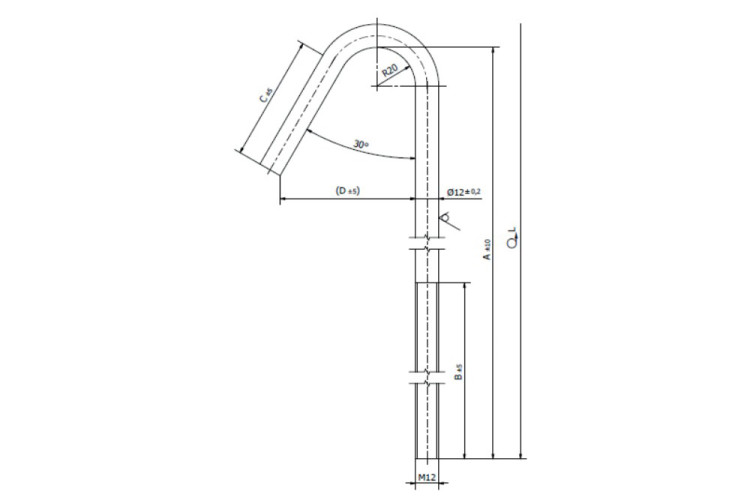

- conveyor suspension elements